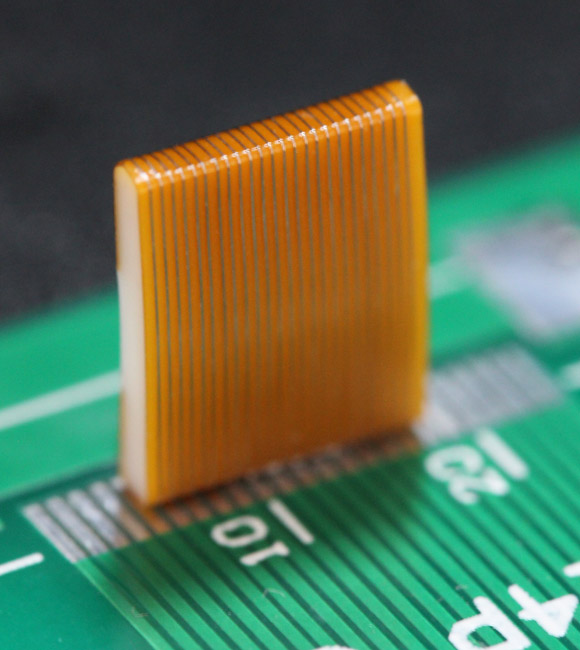

Elastomeric connectors have revolutionized the field of electronic interconnects, offering unparalleled benefits that contribute to their widespread adoption across various industries. In this post, we will delve into the reasons behind the performance of elastomeric connectors, focusing on their ease of assembly, remarkable shelf life, and impressive working life. By understanding these key attributes, engineers, designers, and industry professionals can harness the full potential of elastomeric connectors in their applications, driving innovation and performance.

- Ease of Assembly:

- One of the standout features of elastomeric connectors is their ease of assembly, which significantly streamlines the manufacturing process and enhances overall efficiency. Unlike traditional connectors that may require intricate soldering or complex assembly procedures, elastomeric connectors offer a straightforward installation process. Their flexible and compressible nature allows for simple insertion between mating surfaces, eliminating the need for specialized tools or equipment. This ease of assembly translates to cost savings and reduced assembly time, making elastomeric connectors a preferred choice for high-volume production environments.

- Long Shelf Life:

- Another compelling aspect of elastomeric connectors is their remarkable shelf life, which ensures reliability and consistency over extended periods. Unlike certain connector types that may degrade over time or exhibit performance issues due to environmental factors, elastomeric connectors maintain their integrity and functionality even after prolonged storage. This attribute is particularly advantageous for applications requiring components to be stocked for future use or deployed in environments with stringent shelf life requirements. Whether stored in controlled environments or exposed to varying conditions, elastomeric connectors retain their properties, providing peace of mind to manufacturers and end-users alike.

- Long Working Life:

- In addition to their impressive shelf life, elastomeric connectors boast a long working life, delivering reliable performance throughout their operational lifespan. The inherent durability and resilience of elastomers allow these connectors to withstand mechanical stresses, environmental hazards, and repetitive mating cycles without compromising functionality. Whether subjected to vibration, shock, temperature fluctuations, or moisture exposure, elastomeric connectors maintain electrical continuity and ensure secure connections, making them suitable for mission-critical applications where reliability is paramount.

- Field Replaceability:

- Elastomeric connectors offer the unique advantage of field replaceability, allowing for easy maintenance and repair in real-world applications. Unlike some traditional connectors that may require specialized tools or equipment for replacement, elastomeric connectors can be quickly swapped out in the field, minimizing downtime and maximizing operational efficiency. This feature is particularly valuable in mission-critical environments where rapid troubleshooting and component replacement are essential for minimizing disruptions and ensuring continuous operation.

- Larger Contact Area:

- Another notable benefit of elastomeric connectors is their ability to provide a larger contact area compared to certain alternative connector types. The broader contact surface enhances electrical conductivity and ensures robust connections between mating surfaces, thereby reducing the risk of signal loss, impedance mismatch, or intermittent connections. This larger contact area also contributes to improved signal integrity and reduced signal attenuation, making elastomeric connectors ideal for high-speed data transmission and sensitive electronic applications where signal fidelity is paramount.

- Reduced Contact Force Requirements:

- Elastomeric connectors require less contact force to establish and maintain electrical connections compared to some traditional connectors, such as spring-loaded pins or rigid connectors. The inherent compliance and elasticity of elastomers enable them to conform to irregularities and surface variations, facilitating low-force mating between connector interfaces. This reduced contact force minimizes the risk of mechanical stress on delicate components, PCBs, or mating surfaces, ensuring reliable connections without exerting excessive pressure or causing damage. As a result, elastomeric connectors are well-suited for applications where gentle mating and low-contact-force requirements are essential.

- Additional Benefits of Elastomeric Connectors:

- Beyond the aforementioned advantages, elastomeric connectors offer a host of additional benefits that contribute to their versatility and utility in diverse applications. These include resistance to environmental factors such as moisture, chemicals, and temperature extremes, ensuring reliability in harsh operating conditions. Elastomeric connectors also exhibit excellent shock and vibration resistance, making them ideal for rugged environments and applications subject to mechanical stresses. Furthermore, their inherent flexibility enables them to accommodate misalignment and tolerances, ensuring consistent performance even in challenging installation scenarios.

Elastomeric connectors stand out as versatile and reliable solutions for a wide range of electronic interconnect challenges. Their ease of assembly, long shelf life, and extended working life make them indispensable components in various industries, from consumer electronics to aerospace and beyond. By leveraging the benefits of elastomeric connectors, manufacturers can enhance product performance, streamline assembly processes, and deliver exceptional value to customers. As technology continues to advance, elastomeric connectors remain at the forefront of innovation, driving progress and enabling next-generation electronic systems.