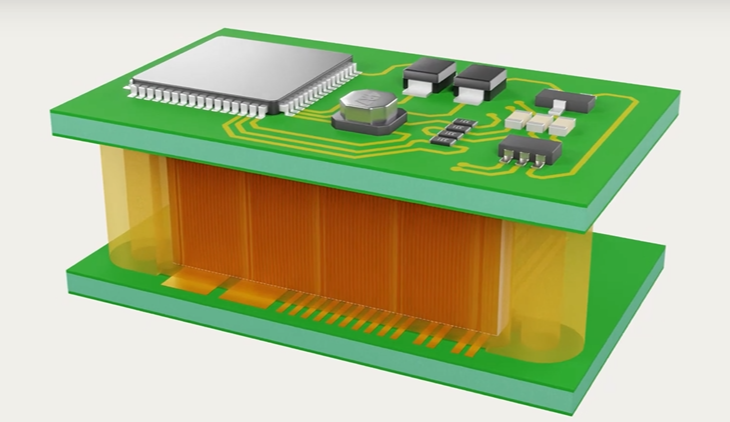

Elastomeric connectors offer unparalleled versatility in terms of geometry. This allows for customization to suit a myriad of application requirements. From standard shapes to more complex configurations, the flexibility of elastomers enables engineers and designers to tailor connectors precisely to their needs.

Understanding Connector Geometry

- Connector Length

- The length of the connector (Lc) is a function of the contact pad layout. To guarantee full coverage of the contact pads including any possible shifting, the connector length is generally .025” (0.64mm) greater than the distance from the edge of the first pad to the edge of the last pad.

- Connector Length (Lc) = (N – 1) Pp + Wp + .040” (1.0mm) where N = the number of contact pads, Pp = Pitch of contact pads, and Wp is width of the pad.

- Connector Height

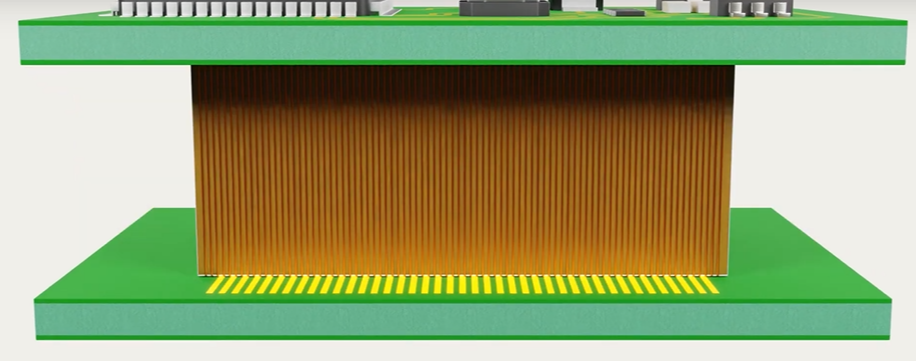

- The most critical dimension with respect to connector performance is height (Hc). Deflection in the z-axis or the height direction is essential to the functionality of an elastomeric connector. Too much deflection may create excessive forces that could result in bowing of the PCB while too little deflection could result in marginal contact that may not be reliable under certain conditions. Therefore to provide reliable, consistent performance, the connector height must be carefully chosen and must take into account the board separation dimension as illustrated above. Z-Axis recommends that under worst case conditions, the connector is designed to allow for a minimum deflection equivalent to 5% of the connector height. To do this, the largest possible board separation must be compared to the shortest possible connector (including tolerances). Typically, the tolerance for the height of the connector is +/- .005” (0.125mm). The following formula will determine the optimal connector height for your application.

- Connector Height (Hc) = ((Board Separation + tolerance) / .95) + Connector Height Tolerance where .005” (0.125mm) is the default connector height tolerance.

- When proper care is taken in determining the connector height, Z-Axis elastomeric connectors will offer consistent results even under conditions such as shock, vibration and environmental extremes.

- Connector Width

- The width of the connector (Wc) is a relative dimension and should be selected based on several criteria. To provide adequate contact area, the width of the connector must be large enough to guarantee that the connector will mate properly with the contact pads even under worst-case conditions. Therefore, the minimum recommended connector width is .020” (0.5mm). Although wider connectors include more conductive material, they also include additional silicone. Since silicone is not a compressible material, it must be displaced when the connector is assembled. Excessively wide connectors should be avoided to minimize the deflection forces of the connector. Since the connector will be deflected when it is assembled, the ratio of connector height to width must not be too high to avoid buckling or folding of the connector. This may also be addressed with the connector housing design to provide proper support. In general, the following equation will offer acceptable width values based on a given connector height (Hc).

- Connector Width (Wc) = Hc / 2.5 (may range from 1 to 5)

Optimizing Performance Through Geometry

The geometry of elastomeric connectors plays a crucial role in optimizing their performance. By carefully selecting the shape and dimensions of the connector, engineers and designers can ensure optimal electrical conductivity, mechanical stability, and environmental resilience. Whether it’s accommodating specific board layouts or maximizing contact area, the right geometry can significantly enhance the connector’s functionality and reliability.

Tailored Solutions for Unique Applications

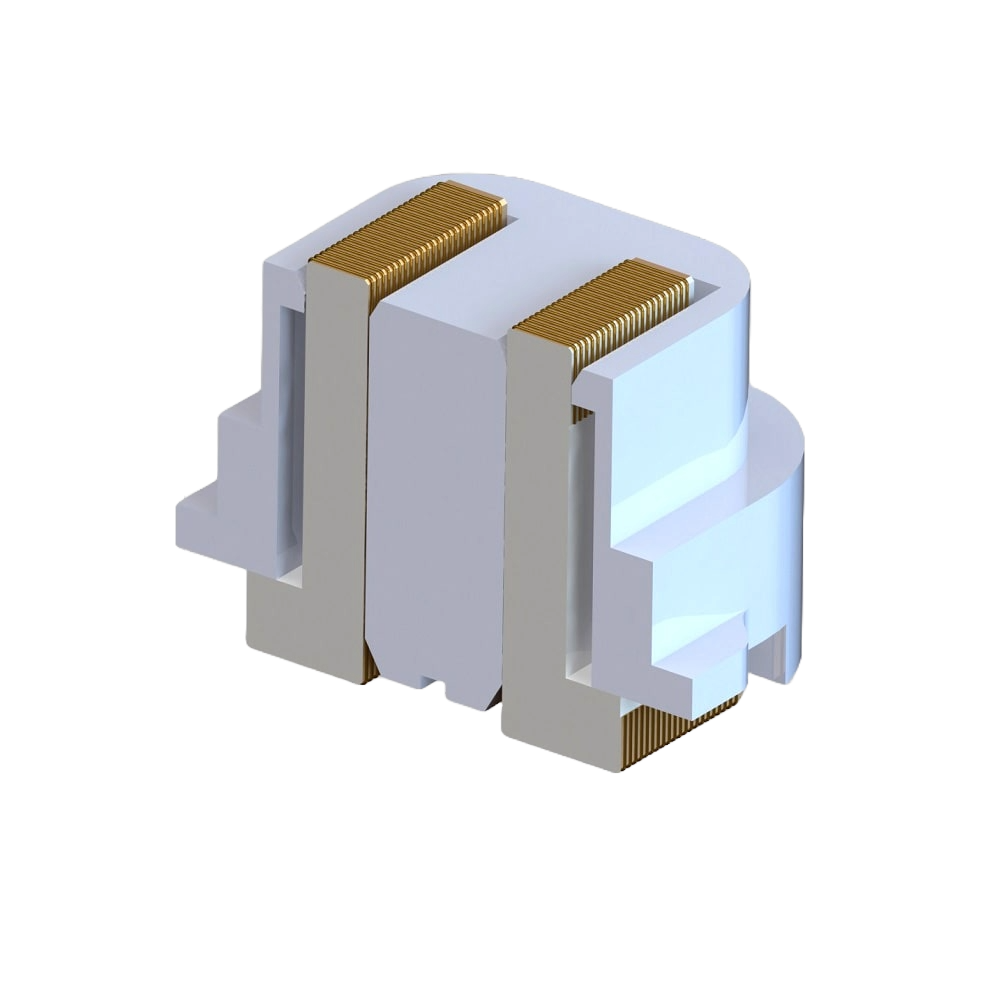

One of the key advantages of elastomeric connectors is their ability to be customized to meet the unique requirements of each application. Whether it’s integrating with irregularly shaped components or adapting to challenging environmental conditions, elastomeric connectors can be designed with specific geometries to address these challenges effectively. This level of customization ensures that the connector not only fits seamlessly into the application but also delivers optimal performance under real-world conditions.

At Z-Axis Connector Company, we understand that every application is unique, and off-the-shelf solutions may not always suffice. That’s why we specialize in providing tailored solutions that precisely match the geometry of your housing or shell components. Our experienced engineers work closely with clients to assess their specific requirements and design elastomeric connectors with custom geometries that seamlessly integrate with their enclosures. Whether it’s accommodating complex contours, aligning with mounting features, or ensuring optimal sealing, we leverage advanced design and manufacturing capabilities to deliver connectors that fit like a glove. By customizing connector geometry to fit shells or housing, we ensure not only a perfect fit but also enhanced performance and reliability in real-world applications.

Balancing Form and Function

In addition to meeting technical requirements, the geometry of elastomeric connectors also plays a crucial role in the overall design aesthetics and manufacturability. By striking the right balance between form and function, designers can create connectors that not only perform flawlessly but also enhance the visual appeal of the final product. Whether it’s sleek and compact connectors for consumer electronics or rugged and robust designs for industrial applications, elastomeric connectors offer endless possibilities in terms of geometry.

Looking Ahead: Innovations in Connector Geometry

As technology continues to evolve, so too does the field of connector design. Innovations in materials science and manufacturing techniques are enabling engineers to push the boundaries of connector geometry, opening up new possibilities for applications across industries. From advanced 3D-printed geometries to micro-scale connectors for IoT devices, the future of elastomeric connectors is full of exciting opportunities for innovation and discovery.

Contact us today!