At Z-Axis Connector Company, we pride ourselves on tackling unique challenges and providing customized solutions where typical, off-the-shelf connectors fall short.

Recently, we were approached with a critical design requirement: developing heat-resistant connectors with precise tolerances to withstand demanding electronic assembly processes. Traditional manufacturing methods could only achieve tolerances of 5 thousandths, which was insufficient for our stringent standards.

Seeking Precision and Durability

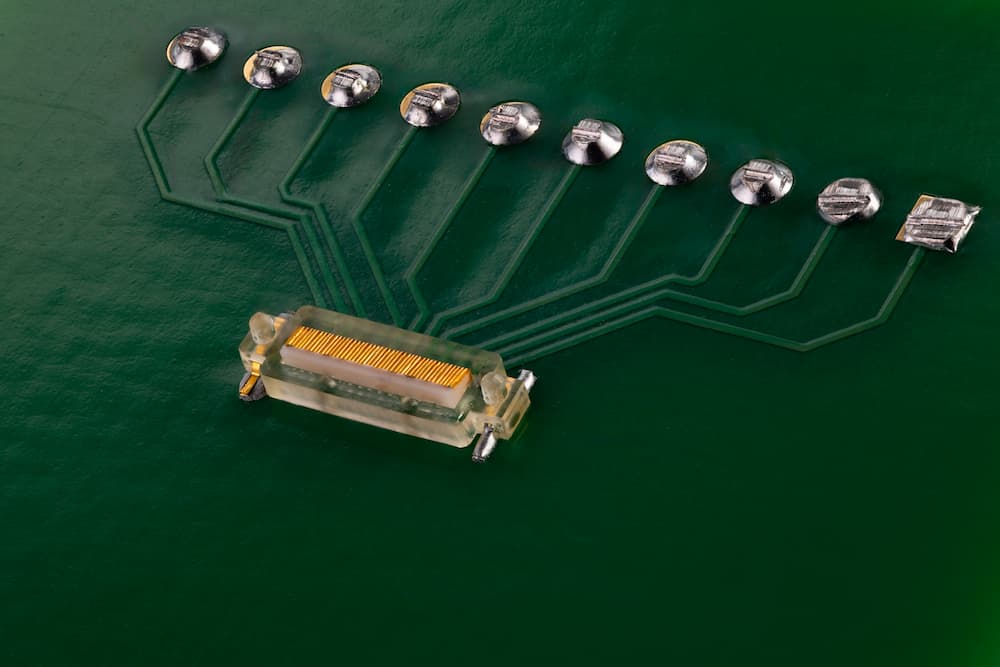

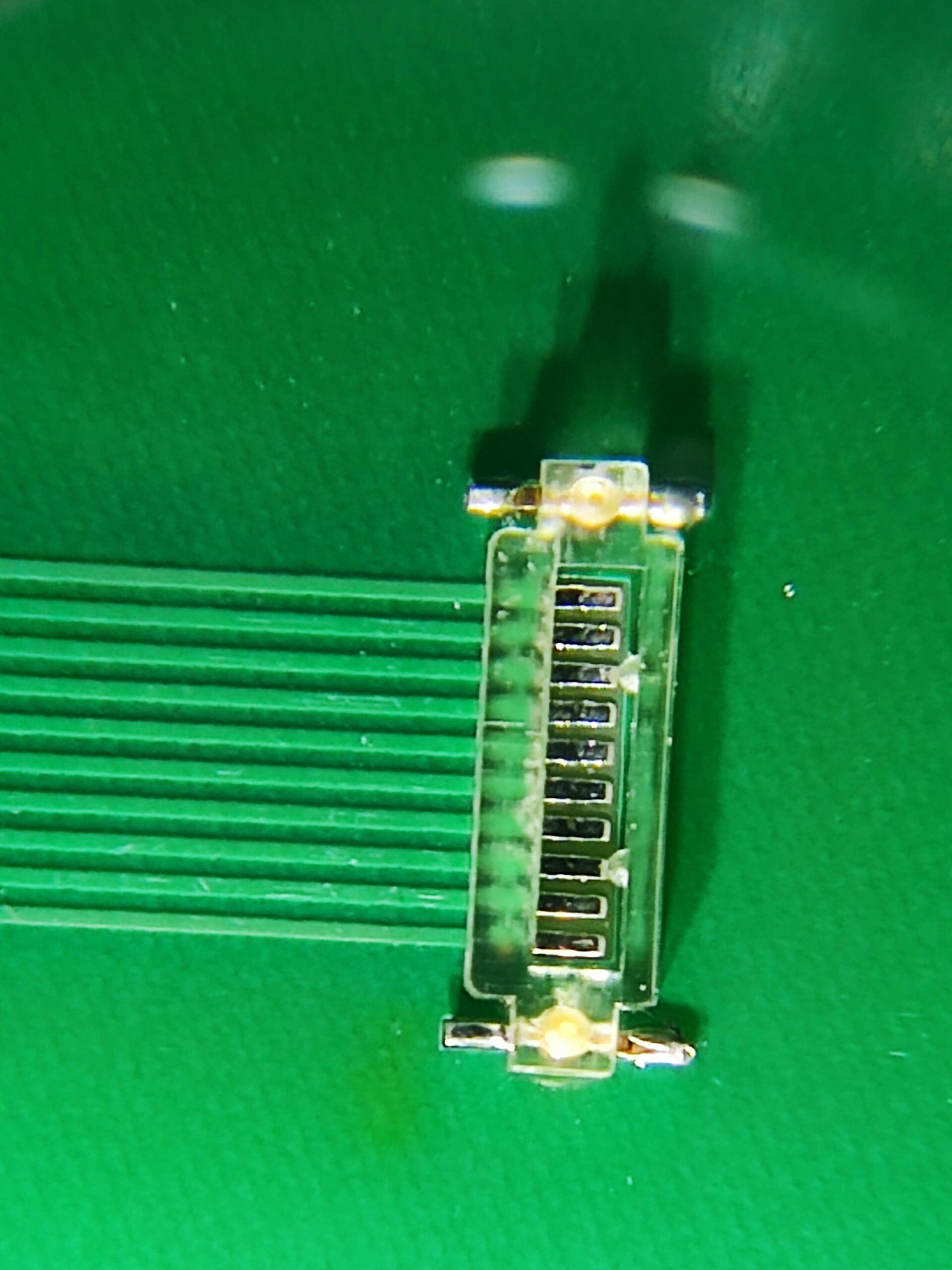

Driven by the need for higher precision and enhanced performance, we turned to micro-precision 3D printing technology, BMF. With our advanced manufacturing capabilities, achieving tolerances of 1 or 2 thousandths became a reality, opening up new possibilities for developing compact, high-performance connectors.

One of our primary challenges was ensuring the connectors could withstand the high-heat soldering processes required in traditional electronic assembly. Our elastomeric connectors needed to endure temperatures up to 237°C during a 7.5-minute solder reflow cycle without compromising their integrity. Utilizing 3D Systems Figure 4® HI TEMP 300-AMB material, engineered to withstand temperatures up to 300°C, provided the perfect solution for our new connector. This breakthrough allowed us to integrate 3D printed connectors seamlessly into standard electronic system manufacturing techniques.

Revolutionizing Connector Manufacturing

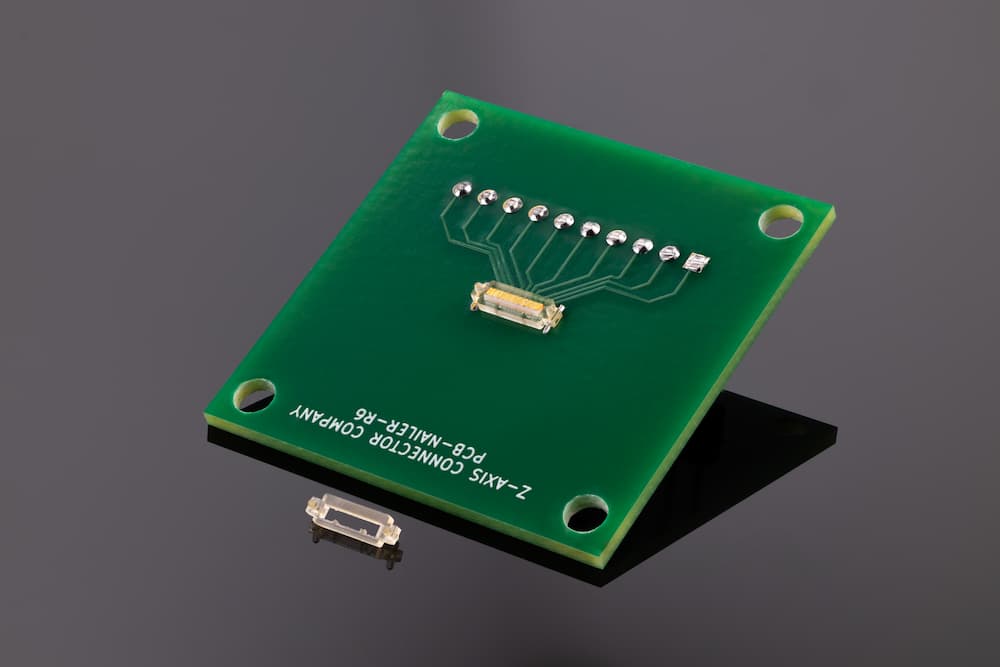

With this new technology, we were also able to transition towards surface mount components, eliminating the need for through-hole accommodations. This innovation enhanced the efficiency of our electronic assemblies, enabling more compact designs and saving valuable board space, thereby meeting the evolving demands of modern electronics.

Conclusion

Z-Axis Connector Company is able to push the boundaries of what is achievable in connector manufacturing. Our new series of heat-resistant connectors not only surpass industry standards but also highlight the potential of micro-precision 3D printing in delivering high-quality, cost-effective solutions.

By leveraging cutting-edge manufacturing technology, we have set a new benchmark for precision and innovation in the connector industry. We are excited about the future and the continued advancements that will redefine what is possible in electronic connector design and manufacturing.

Interested in learning more about our heat-resistant connectors or discussing your specific application needs? Contact us today and discover how Z-Axis Connector Company can help you achieve unparalleled performance and reliability in your electronic assemblies.