If you’re like most engineers, elastomeric connectors don’t get attention until late in the design process. Usually right before bring-up or testing. But the right connector, chosen early, eliminates re-spins, improves signal integrity, and simplifies your entire mechanical stack-up.

At Z-Axis Connector Company, we work with engineers every day to refine elastomeric interconnects for displays, sensors, RF boards, test fixtures, medical devices, and more. Below are the most common questions we hear, and the answers that help teams avoid delays, failed prototypes, and costly rework.

1. How Much Compression Do I Actually Need?

Compression is the heart of elastomeric connector performance. Too little and contact resistance jumps. Too much and you damage pads or overstress the connector.

Typical guidance

- 5-20% compression for most Z-Axis conductive rubber connectors

- Higher compression for very fine pitch or high-current applications

- Lower compression when mating delicate PCB pads or flex circuits

We help you calculate compression force and stack-up tolerance so you know exactly what height to design for, before machining fixtures or PCBs.

2. What Pad Plating Works Best?

Your pad plating choice is one of the biggest factors in long-term connector performance, especially for elastomeric contacts. Some finishes wear quickly or oxidize, while others maintain stable, low-resistance contact over thousands of cycles.

Best options (ranked):

1. Hard Gold (Electroplated Gold over Nickel)

The preferred choice for elastomeric connectors.

- Extremely durable

- Best for high-cycle, test fixtures, and repetitive compression

- Excellent wear resistance

- Long-term stable contact resistance

If your design involves hundreds or thousands of actuations, or if uniform reliability is critical, hard gold is the top recommendation.

2. ENIG (Electroless Nickel Immersion Gold)

Most common and stable finish for production PCBs.

- Great for fine pitch

- Consistent pad height

- Good corrosion resistance

- Suitable for most elastomer applications

- Lower wear resistance than hard gold

3. ENEPIG

Premium option for demanding projects.

- Excellent wirebond and solder compatibility

- Very stable for high-frequency or mixed-signal systems

- Good for harsh environments

- Slightly more expensive

Design teams often choose ENEPIG when they’re unsure whether pads will be wirebonded, soldered, or used with elastomers.

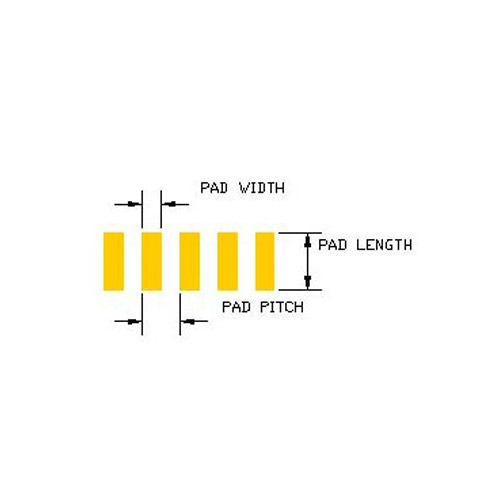

3. How Tight Do My PCB Tolerances Need to Be?

Elastomeric connectors are extremely forgiving, but not infinitely.

Critical dimensions:

- Pad width and spacing

- Total compressed height

- Alignment features or pockets

- Registration of top and bottom pads (for vertical interposers)

We’ll give you a clear tolerance envelope so your board house doesn’t over-tighten (or under-tighten) specs.

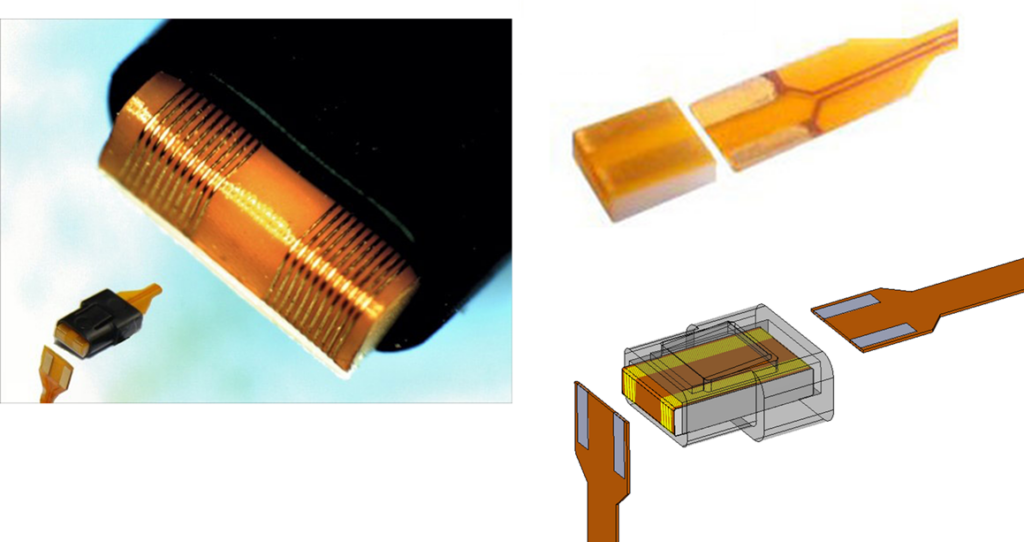

4. Can I Use Elastomeric Connectors for High-Frequency Signals?

Yes, if the connector is designed correctly.

Z-Axis elastomers can handle high-frequency digital or RF signals, but pitch, column structure, and stack-up must be optimized.

We provide SI (signal integrity) recommendations, including:

- Recommended max trace length disparity

- Impedance-friendly pad geometries

- Compression uniformity guidelines

- When to choose Z-Flat, Z-Wrap, or custom profiles

5. How Do I Keep My Mechanicals Simple?

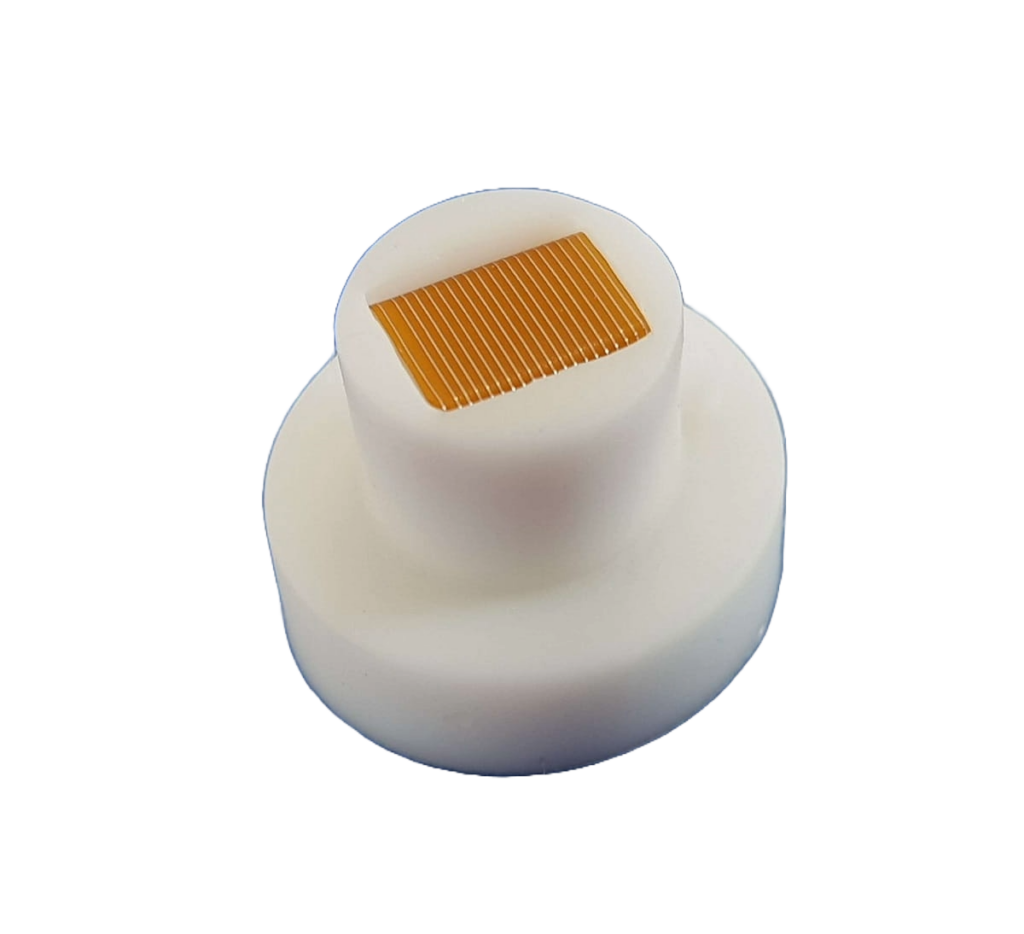

A good elastomer contact system only needs three things:

- Uniform compression across the contact area

- Alignment references (pins, walls, or pockets)

- A controlled height

We routinely help customers eliminate springs, screws, floating plates, and other unnecessary parts. Reducing cost and improving reliability.

6. What’s the Maximum Current I Can Push Through?

This depends on pitch, trace area, and compression. We’ll review your layout and provide exact numbers with derating curves.

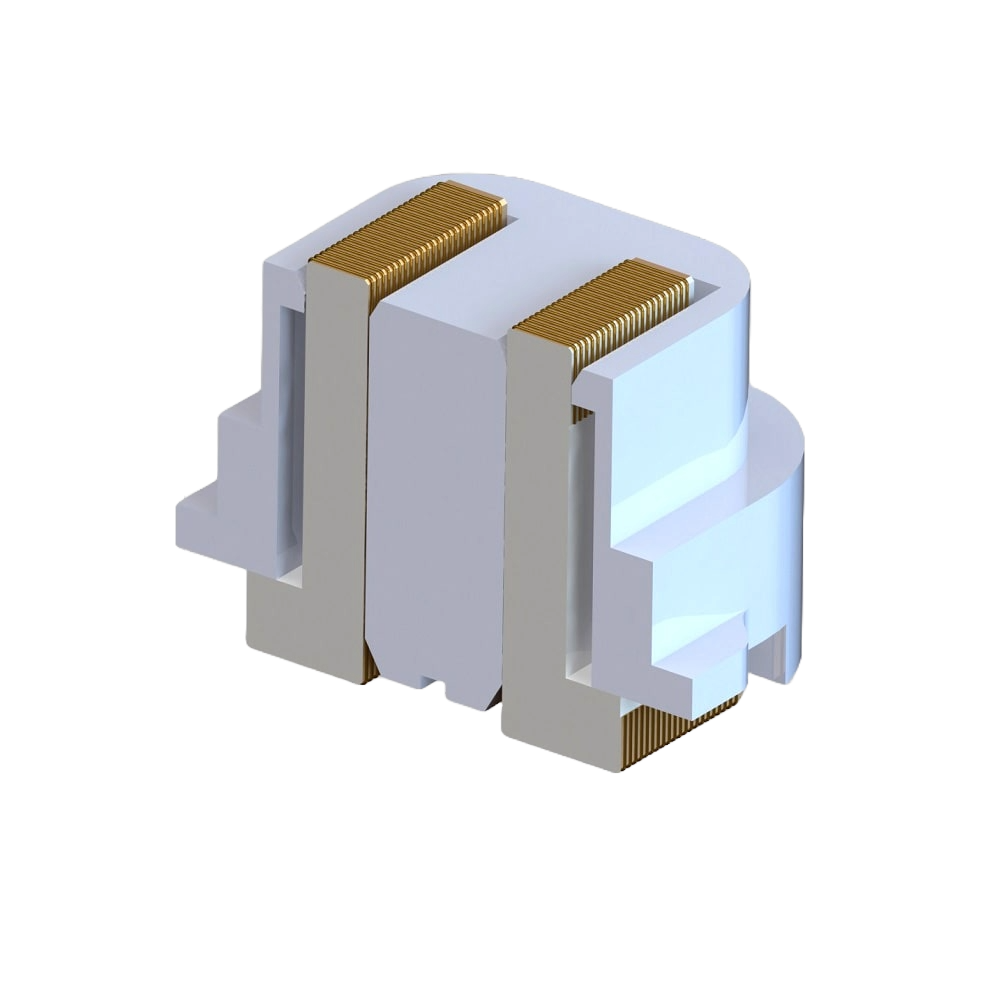

7. Can You Build Custom Connectors?

Yes, almost always!

Whether you need:

- Non-standard pitch

- Custom thickness

- Odd shapes

- Multi-stack assemblies

- Integrated guides or frames

- High-wear test fixture contacts

We design and build custom elastomeric connectors every day for production programs, not just prototypes.

If your geometry looks impossible, send it over. Odds are we’ve already made something similar.

Choosing the Right Elastomer Early Saves Time, Money, and Stress

Choosing the right connector early keeps your team moving, ensures signal integrity, and eliminates last-minute mechanical gymnastics.

If you want help selecting the best elastomer for your next project, or want a quick DFM review, our engineering team is always happy to take a look.