At Z-Axis Connector Company, we specialize in providing innovative solutions for complex electronic interconnects. One of the most versatile and effective solutions is the elastomeric connector. Unlike traditional connectors, elastomeric connectors create reliable electrical contact between printed circuit boards (PCBs) through precise compression, eliminating the need for soldering or permanent attachments.

The Mechanics of Elastomeric Connectors

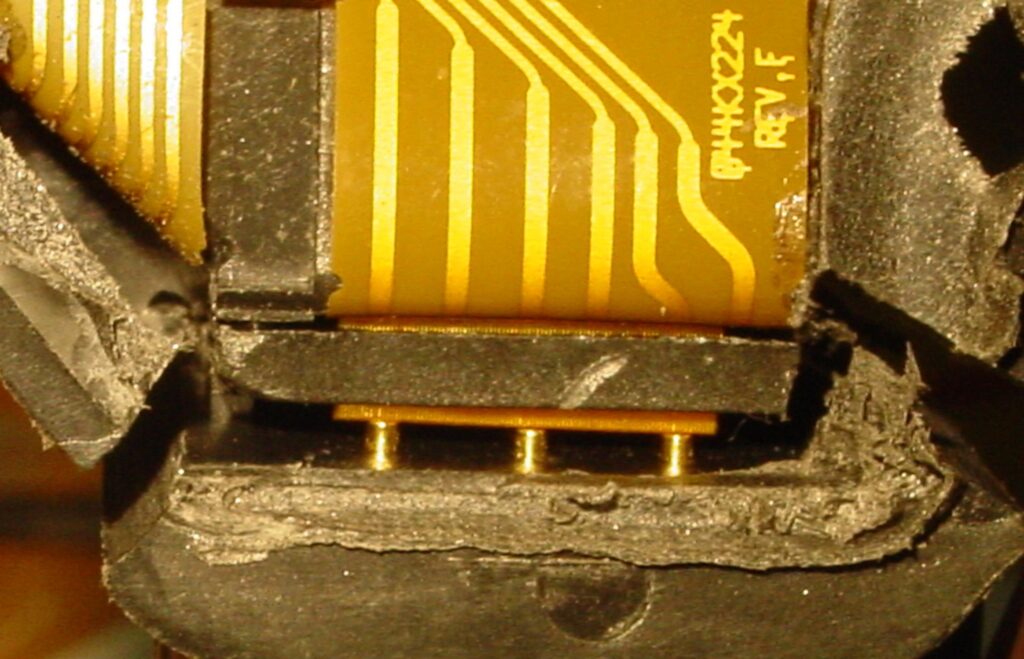

Elastomeric connectors consist of a flexible polymer embedded with conductive elements. When compressed between two PCBs, the connector conforms to the surfaces of the boards, ensuring consistent electrical contact across all circuits. This simple yet highly effective principle enables engineers to achieve high-density connections without compromising performance or reliability.

Compression is key: the elastomer’s flexibility allows it to absorb mechanical tolerances and surface irregularities, maintaining reliable contact over thousands of cycles. This eliminates many of the issues associated with rigid connectors, including poor alignment, contact fatigue, and wear over time.

Advantages of Elastomeric Connections

- Uniform Contact Across All Circuits

The elastomer ensures that every conductive pathway is engaged, providing stable electrical performance even in boards with complex layouts. - Durable Performance in Harsh Conditions

Elastomeric connectors maintain their integrity under mechanical stress, vibration, and thermal cycling. This makes them ideal for applications where reliability is critical. - Simplified Assembly and Maintenance

Since no soldering or permanent hardware is required, elastomeric connectors reduce assembly time and allow for rapid board-to-board testing and replacement. This is particularly valuable in prototyping and production environments where design iterations are frequent. - High-Density Interconnect Capability

These connectors are ideal for high-density PCBs where space is limited. Their compact form factor allows engineers to maximize board real estate without sacrificing connectivity.

Real-World Applications

Elastomeric connectors are widely used across industries, including:

- Consumer Electronics: Connecting flexible or rigid PCBs in compact devices such as smartphones, tablets, and wearable technology.

- Medical Devices: Ensuring reliable, repeatable connections in diagnostic and monitoring equipment where precision is essential.

- Industrial Automation: Withstanding high vibration and repeated assembly cycles in production equipment.

- Testing and Prototyping: Allowing engineers to quickly connect and disconnect boards during development and quality assurance processes.

Why Z-Axis Connector Company

With decades of experience in custom connector design, Z-Axis Connector Company offers:

- Precision Engineering: Custom elastomeric connectors designed to fit your exact board specifications.

- Reliable, Long-Term Performance: Materials and designs optimized for high durability and consistent performance.

- Simplified Integration: Solutions that reduce assembly time and streamline production workflows.

By leveraging elastomeric connectors, engineers can reduce assembly complexity, increase reliability, and accelerate time-to-market for their electronic products.

Discover the difference an elastomeric connector can make in your next project. Contact Z-Axis Connector Company today to explore custom solutions tailored to your application.