Background

In aerospace, defense, and industrial environments, connectors must operate reliably in extreme conditions. While most interconnect solutions are tested for high-heat environments, performance in sub-zero temperatures is equally critical, particularly for applications such as satellites, unmanned systems, and outdoor sensors deployed in polar or high-altitude regions.

The Challenge

A customer needed a reliable interconnect solution that would maintain electrical continuity and mechanical stability in extreme cold environments (down to –55 °C). Standard board-to-board connectors using rigid pins and soldered interfaces were prone to micro-cracking, loss of contact pressure, and intermittent signals at these temperatures.

The Z-Axis Solution

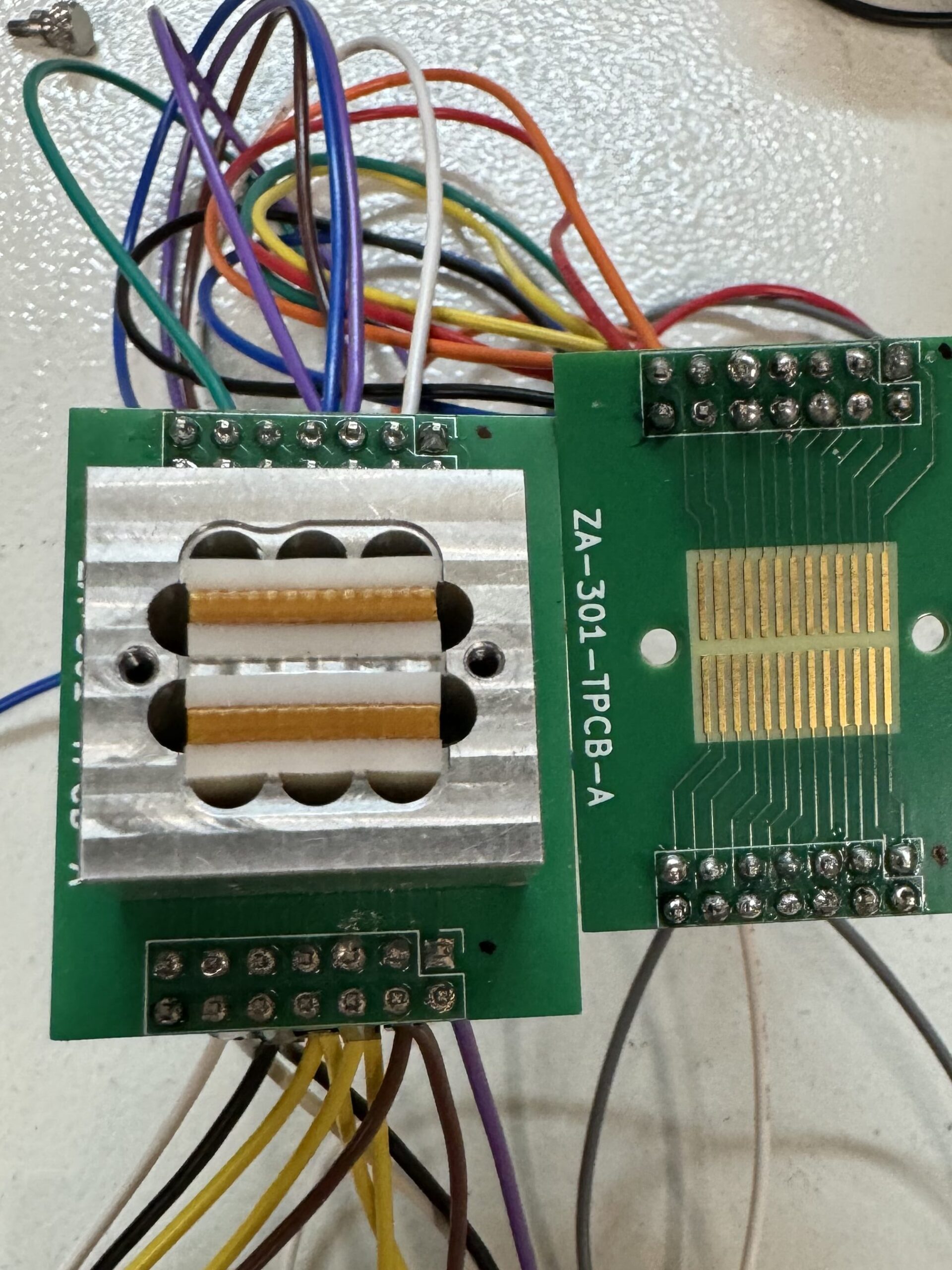

Z-Axis designed a custom low-temperature elastomeric connector engineered for resilience in cryogenic conditions:

- Elastomeric Contact Matrix – Maintains compliance and consistent contact force despite thermal contraction.

- Shock & Vibration Resistance – Absorbs mechanical stress without losing alignment, ideal for aerospace and defense applications.

- Customizable Pitch & Profile – Tailored to customer’s PCB stack-up, eliminating the need for redesigns.

- Proven Low-Temperature Stability – Materials and adhesives tested to retain flexibility and conductivity at extreme cold.

Results

The Z-Axis connector not only met the customer’s –55 °C operating requirement, but also demonstrated extended reliability during thermal cycling (from –55 °C to +125 °C). This eliminated failure points seen in conventional connectors, reduced maintenance cycles, and enabled long-term operation in remote and mission-critical environments.

Applications

- Aerospace and satellite electronics

- Outdoor radar and sensor systems

- High-altitude UAVs and drones

- Military communications equipment

Why Z-Axis?

By leveraging elastomeric technology, Z-Axis delivers interconnects that perform where traditional connectors fail. Our low-temperature solutions ensure signal integrity, durability, and design flexibility for customers working at the edge of engineering limits.