As electronic systems continue to evolve toward smaller form factors, higher signal density, and tighter mechanical tolerances, the interconnect often becomes one of the most challenging parts of the design. Traditional soldered or pin-based connectors can introduce limitations related to size, rigidity, and long-term reliability.

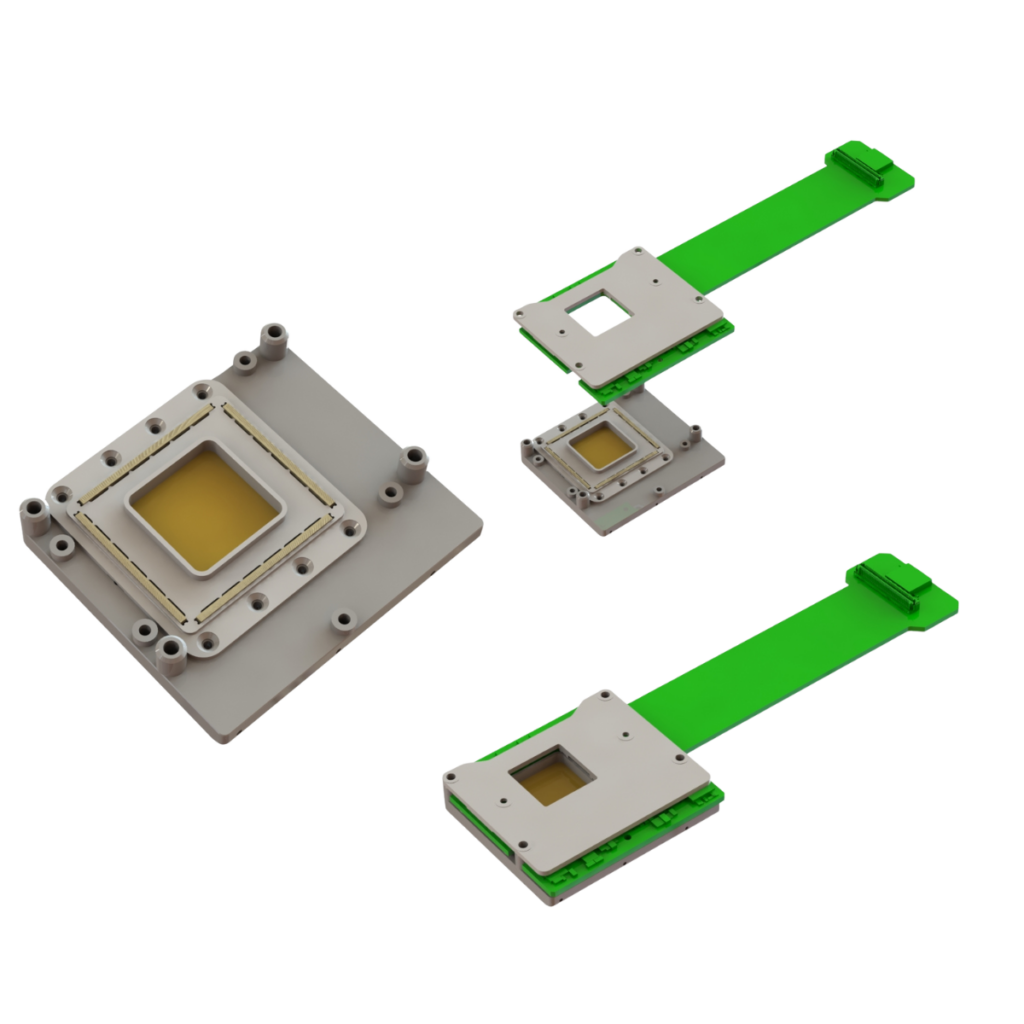

Elastomeric connectors provide a fundamentally different approach. This application demonstrates how Z-Axis Connector Company’s elastomeric connectors enable reliable, high-density board-to-board interconnects while simplifying mechanical integration and assembly.

The Interconnect Challenge in Modern Electronics

Board-to-board interconnects must satisfy multiple competing requirements at once:

- Increasing signal density in shrinking footprints

- Consistent electrical performance across tolerance variation

- Low-profile mechanical integration

- Resistance to vibration, thermal cycling, and repeated assembly

- Manufacturability and long-term serviceability

Rigid connectors often force compromises, larger footprints, tighter tolerances, or permanent solder joints that make rework difficult. As designs scale in complexity, these compromises can increase cost and risk.

Elastomeric Connectors: A Different Design Philosophy

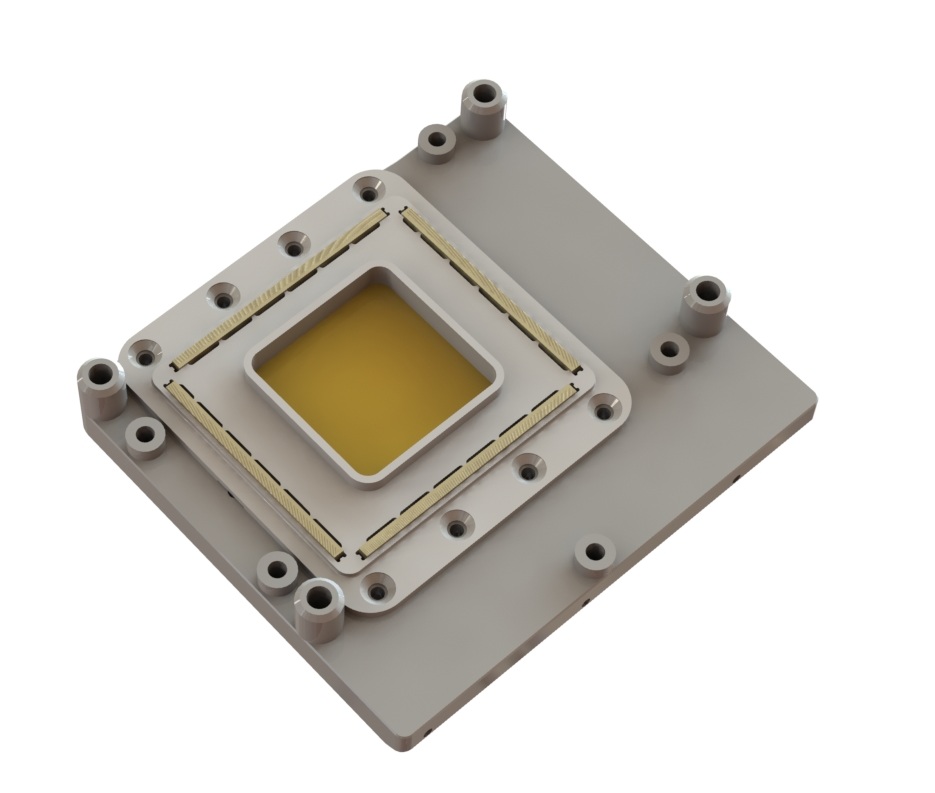

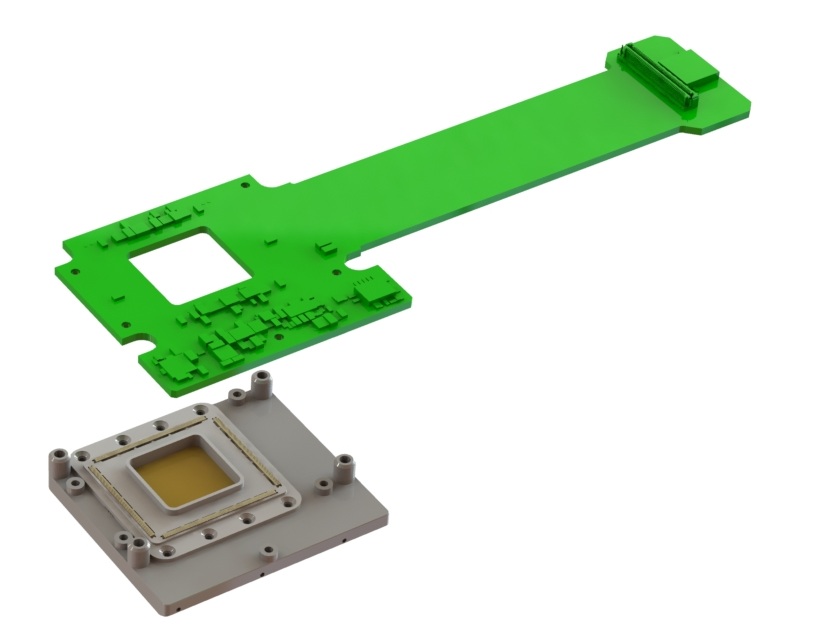

Elastomeric connectors conduct only in the Z-axis, using alternating conductive and insulating layers. When compressed between two sets of PCB pads, they create multiple parallel contact points per signal, improving electrical reliability while maintaining isolation between adjacent circuits.

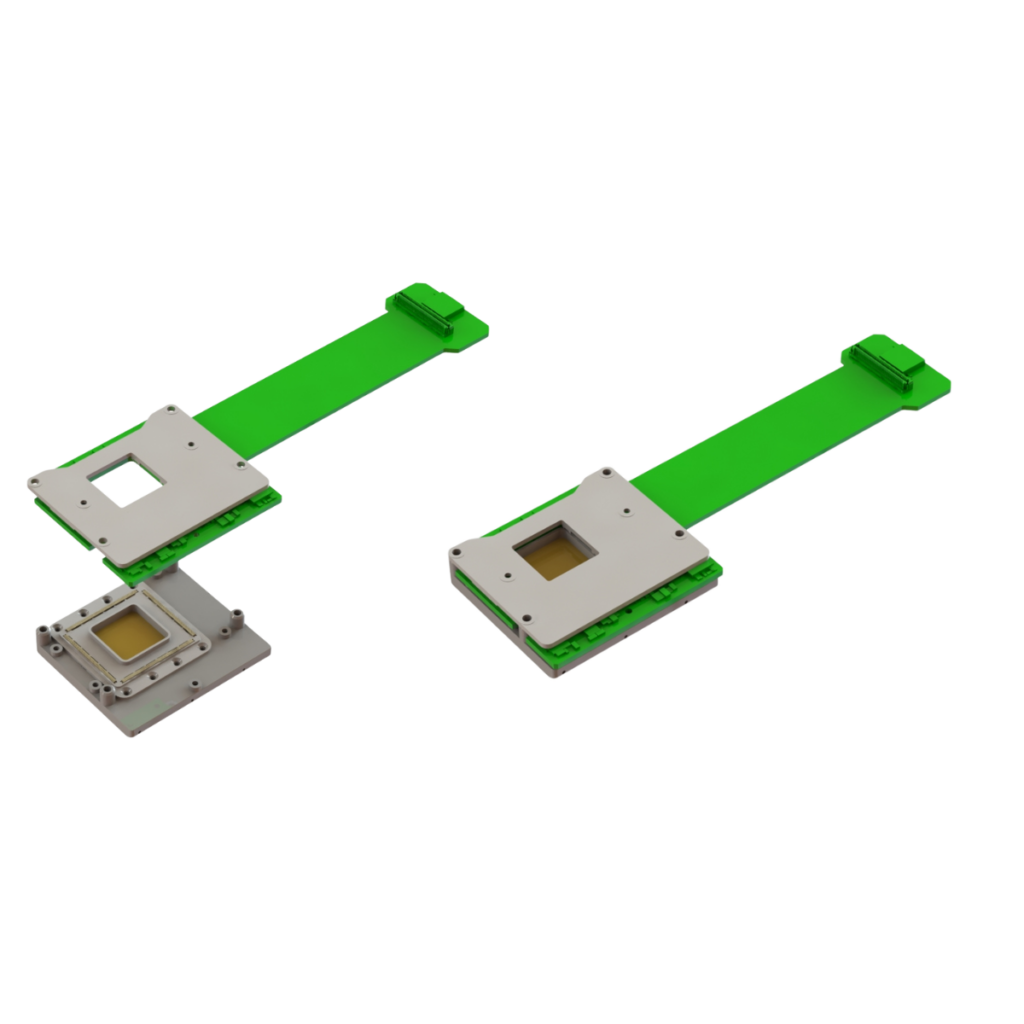

In this application, the elastomeric connector is integrated into a precision compression frame that applies uniform force across the contact area. This ensures repeatable electrical performance while allowing compliance within the mechanical stack-up.

Key Engineering Advantages

1. Mechanical Compliance Without Electrical Tradeoffs

Elastomeric connectors accommodate:

- PCB flatness variation

- Minor misalignment

- Tolerance stack-up across housings and fasteners

This compliance reduces mechanical stress on boards and contacts, improving reliability without sacrificing signal integrity.

2. High-Density Interconnect in a Compact Footprint

Because there are no discrete pins, elastomeric connectors support:

- Fine pitch layouts

- High contact counts in small areas

- Flexible pad geometries

This makes them ideal for compact electronics where board space is at a premium.

3. Low-Profile, Solderless Integration

Elastomeric connectors eliminate the need for:

- Tall connector housings

- Through-hole or SMT solder joints

- Complex mating sequences

The result is a low-profile interconnect that integrates cleanly into enclosed or stacked assemblies.

4. Serviceability and Rework

Without solder joints:

- Boards can be removed and replaced

- Connectors can be serviced independently

- Prototypes and production units benefit from easier debugging and rework

This is particularly valuable in applications where access is limited or systems must be maintained over time.

5. Designed for Production

When properly engineered, elastomeric connectors deliver:

- Controlled compression and contact force

- Repeatable performance across builds

- Long cycle life under repeated assembly

Z-Axis Connector Company designs each connector around the application’s pad geometry, pitch, current requirements, and mechanical constraints, ensuring consistent performance from prototype through production.

Broad Applicability Across Electronics

Because elastomeric connectors are not tied to a specific industry, they are used across a wide range of electronic systems, including:

- Embedded electronics and control boards

- Imaging, sensing, and display modules

- Test and measurement equipment

- OEM and custom electronic assemblies

Any application that benefits from high-density, compliant, solderless interconnects can take advantage of this technology.

Engineering Flexibility Without Compromise

Unlike off-the-shelf connectors, elastomeric interconnects are not constrained by standardized housings or pin counts. This gives designers more freedom early in the design process—allowing mechanical, electrical, and manufacturing considerations to align rather than conflict.

By addressing interconnect challenges at the system level, elastomeric connectors help reduce risk, improve reliability, and simplify assembly.

Designed for Engineers. Built for Production.

If your electronic design requires high-density interconnects, mechanical compliance, and long-term reliability, elastomeric connectors offer a proven and flexible solution.