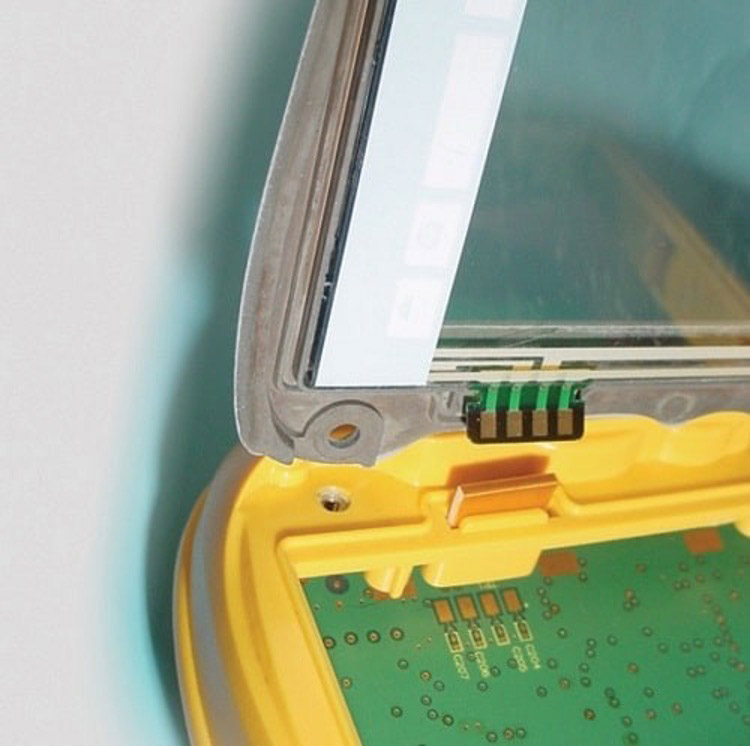

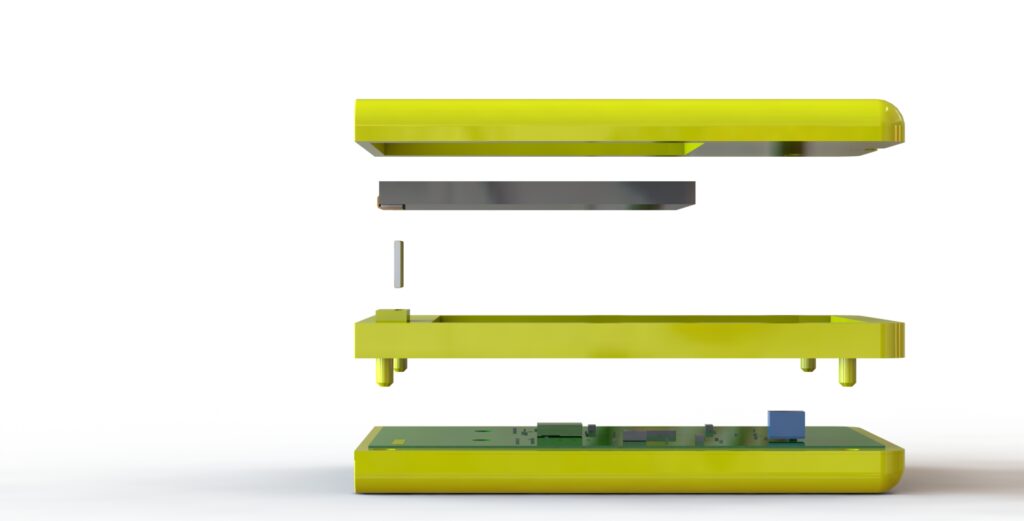

Elastomeric connectors create electrical contact by controlled compression between mating conductive pads. Instead of solder joints or mating connectors, conductivity is achieved through alternating conductive and insulating layers embedded in an elastomeric profile.

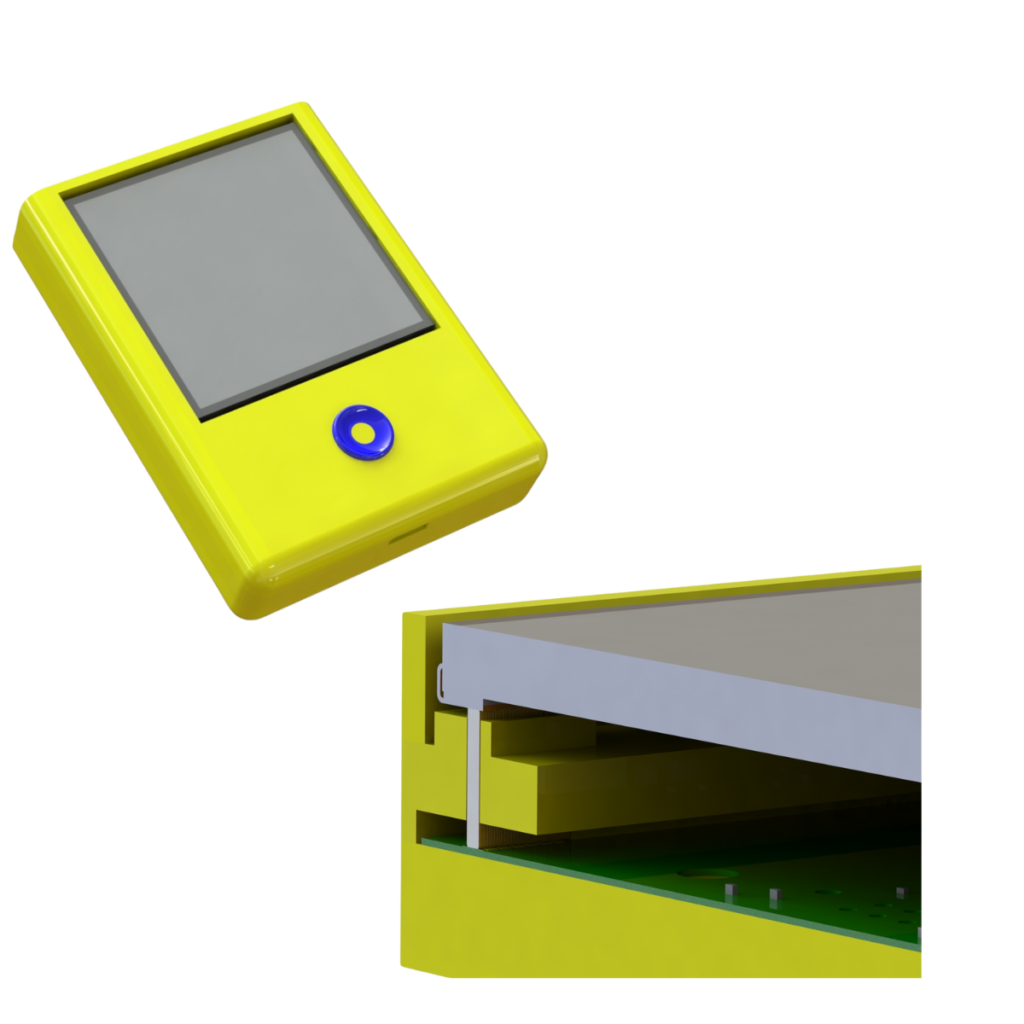

The result is a direct PCB-to-display or PCB-to-PCB interface with minimal Z-height and no permanent electrical bonds.

Key Advantages for Space-Constrained Designs

1. Ultra-Low Profile Interconnect

Elastomeric connectors eliminate the height associated with:

- FFC/FPC connectors

- Board-to-board headers

- Cabled assemblies and strain relief

This enables thinner enclosures, tighter internal packaging, and greater mechanical freedom.

Many displays feature a rigid FFC tail. You can browse a wide range of LCD, OLED, and graphic display modules on popular distributor sites.

2. Single-Piece, One-Step Assembly

From an assembly perspective, elastomeric connectors are intentionally simple:

- One connector component

- One compression plane

- No mating cycles or latching features

This reduces assembly time, minimizes operator error, and improves yield in both low-volume and production environments.

3. No Soldering Required

By eliminating solder joints, elastomeric connectors remove several common failure points:

- Cold solder joints

- Reflow-related damage

- Thermal stress on displays or PCBs

- Rework and repair risk

This makes them particularly well-suited for sensitive displays and mixed-material assemblies.

4. High Contact Density in Minimal Space

Despite their small footprint, elastomeric connectors support high signal counts with consistent electrical performance. When properly compressed and aligned, each conductive layer forms a reliable vertical (Z-axis) connection.

5. Improved Shock, Vibration, and Serviceability

Because electrical contact is maintained through compression rather than rigid metal interfaces, elastomeric connectors perform well in environments subject to:

- Shock and vibration

- Repeated servicing

- Mechanical tolerance stack-ups

Displays and PCBs can be removed and reinstalled without damaging the interconnect.

Designed for Production, Not Just Prototypes

At Z-Axis Connector, our elastomeric interconnects are engineered with manufacturing repeatability in mind. Compression force, pad geometry, alignment features, and material selection are all considered to ensure consistent performance across production volumes.

We routinely support applications including:

- Handheld and portable devices

- Industrial instrumentation

- Ruggedized electronics

- Test and measurement equipment

- Custom display interfaces

Designing with Elastomeric Connectors

Successful integration depends on proper mechanical and electrical design. Key considerations include:

- Pad geometry and plating

- Compression force and retention method

- Alignment and tolerance control

- Environmental sealing requirements

Our engineering team works directly with customers to ensure elastomeric connectors are integrated correctly from the start.

Simplify Assembly. Improve Reliability.

If your design is constrained by space, assembly complexity, or solder-related reliability issues, elastomeric connectors provide a proven alternative.

Contact Z-Axis today to discuss your application.