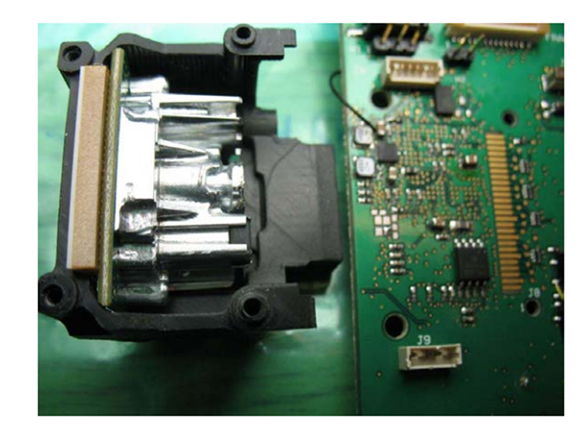

A recent customer approached us with a common but challenging requirement. We were tasked to create a reliable 90-degree board-to-board interconnect in an extremely constrained mechanical envelope, while also supporting high-speed signals up to 5 Gbps.

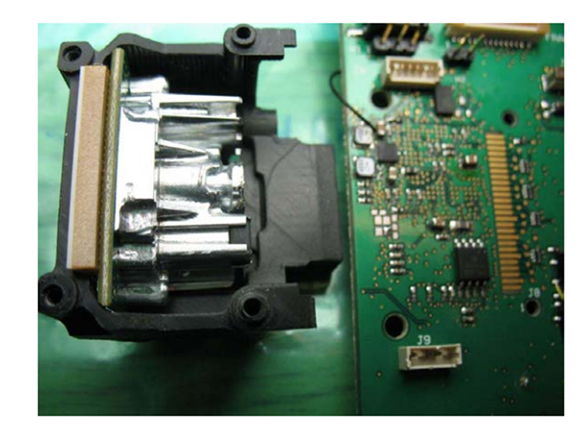

The application involved a compact electronics assembly with a vertically mounted daughtercard interfacing to a horizontal main PCB. Space limitations, vibration exposure, and signal integrity requirements ruled out traditional right-angle connectors and flex circuits early in the design process.

Z-Axis worked directly with the customer to develop a Z-Fill elastomeric connector solution optimized for both the electrical and mechanical constraints of the system.

Application Requirements

The customer’s system imposed several critical constraints:

- True 90-degree PCB orientation with minimal Z-height

- High-speed data lanes up to 5 Gbps

- Tight mechanical tolerances and limited keep-out areas

- Resistance to shock and vibration

- A production-ready solution with repeatable assembly

One representative use case within the system was a high-speed camera module, where signal integrity and connector reliability were particularly critical.

Why Traditional Solutions Fell Short

Conventional interconnect options presented multiple issues:

- Right-angle pin headers lacked the required signal performance and mechanical robustness

- High-density mezzanine connectors consumed excessive board area and Z-height

- Flex circuits added cost, assembly complexity, and long-term reliability concerns

In addition, mating-cycle wear and connector fretting were unacceptable for the expected service life of the product.

Z-Fill Elastomeric Connector Solution

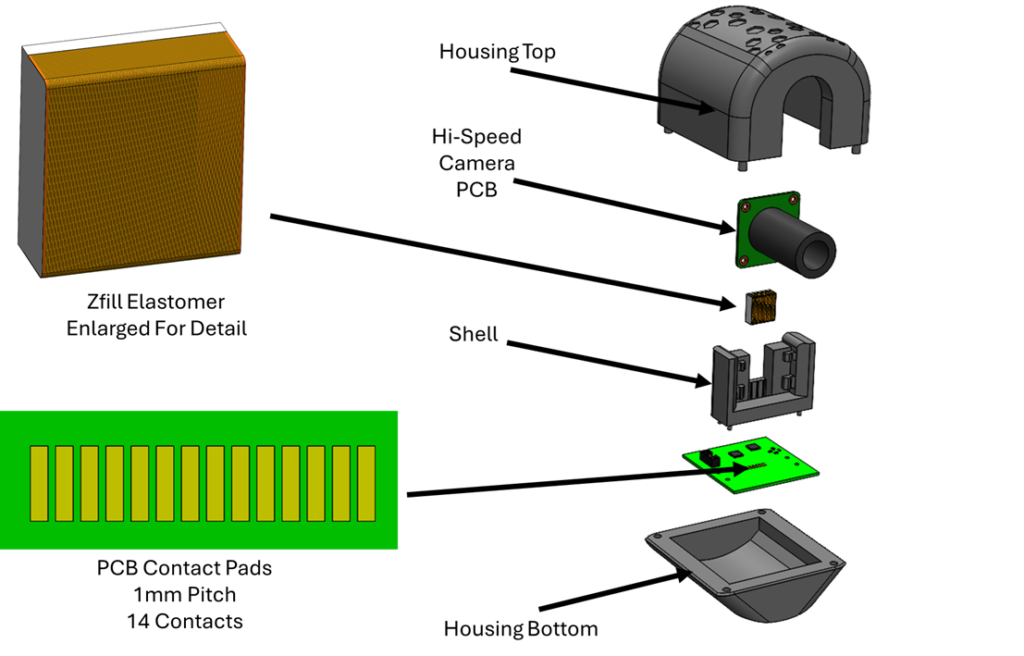

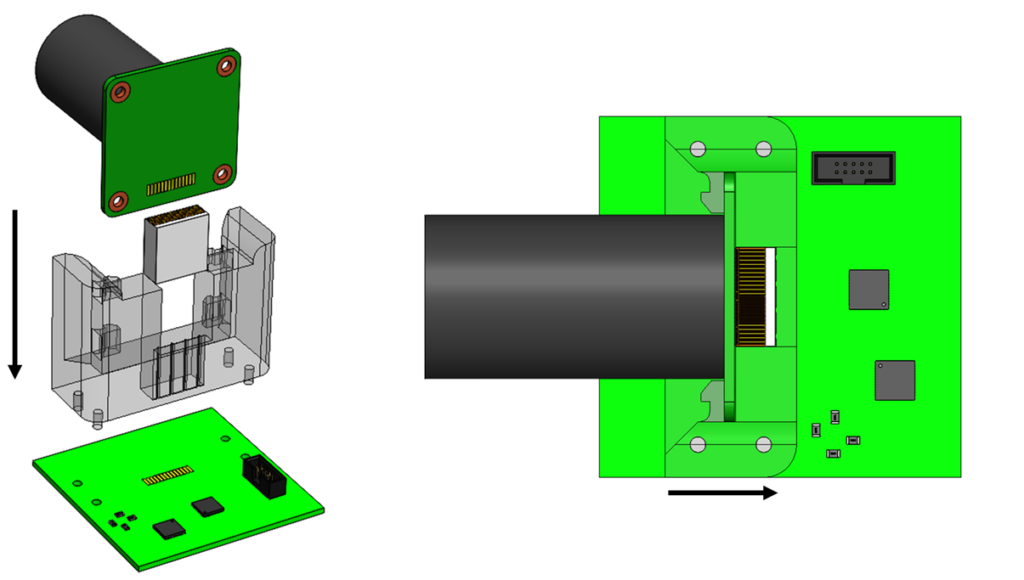

Z-Axis designed a compression-based elastomeric interconnect that enabled direct pad-to-pad contact between the perpendicular PCBs.

Key aspects of the solution included:

- A custom Z-Fill elastomer stack

- A controlled mechanical compression system to ensure consistent contact force across all circuits

- Optimized pad geometry to support high-speed signal integrity at multi-gigabit data rates

By eliminating traditional metal-to-metal mating interfaces, the connector removed common failure mechanisms while maintaining excellent electrical performance.

Electrical and Mechanical Benefits

High-Speed Performance

The short electrical path and absence of connector pins or stubs helped minimize:

- Impedance discontinuities

- Reflections and insertion loss

- Crosstalk between adjacent signals

This made the solution well-suited for 5 Gbps camera interfaces and other high-speed digital applications.

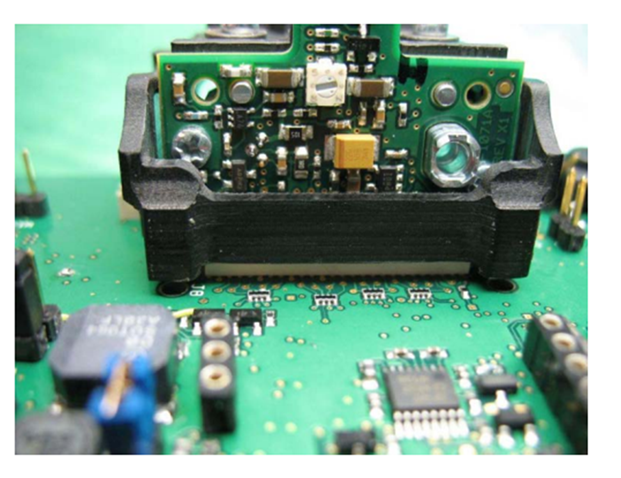

Mechanical Reliability

The compression-based design provided:

- Excellent resistance to shock and vibration

- No wear from mating cycles

- Stable electrical performance over time

Because the connector relies on mechanical compression rather than insertion, it is inherently robust in harsh or mobile environments.

Designed for Production

The final design was engineered for repeatable, high-volume manufacturing, with:

- Simple PCB pad layouts

- Straightforward mechanical stack-up

- No soldering or delicate alignment steps

This resulted in improved assembly yield and reduced long-term maintenance risk for the customer.

A Flexible Approach for 90-Degree Applications

While this application included a high-speed camera module, the same 90-degree elastomeric interconnect approach is applicable to:

- Embedded vision systems

- Sensor modules

- Industrial controls

- Test and measurement equipment

- Compact electromechanical assemblies

Each Z-Fill connector is application-specific, allowing Z-Axis to optimize electrical, mechanical, and environmental performance for the end product.

Partner with Z-Axis Connector Company

Z-Axis Connector Company specializes in custom elastomeric interconnect solutions for challenging board-to-board applications, especially where traditional connectors fall short.

If you’re facing a difficult 90-degree interconnect or high-speed signal challenge, our engineering team can help take your design from concept to production.