Test Fixtures

Z-Axis Soft-Contact Test Fixtures

Many electronic manufacturers, installing parts into products, face testing challenges including the following:

- Damage to or permanent marks on the device under test (DUT)

- Interrupted and inefficient workflow.

- Different testing equipment is required to facilitate different applications, size of DUT as well as FFC versus FPC.

The design features of the Z-Axis Flexible Test Fixture solves these problems. It is simple and intuitive, user friendly, with a durable and rugged design. Unlike other test fixtures, the Z-Axis Flexible Test Fixture’s unique design provides:

- Soft contacts that eliminate damage or permanent markings to the DUT

- Utilizes an easy Lever Actuation that can be repeated for thousands of cycles before any maintenance is required.

- Human scale that mounts to the bench to facilitate smooth and efficient workflow.

- Universal Design: a single Z-Axis Flexible Test Fixture fits most FFC and FPC applications.

What are FFCs and FPCs?

Both FFCs (Flexible Flat Cables) and FPCs (Flexible Printed Circuits) are used to connect electronic devices, but they differ in their construction and design.

Flat flexible cables consist of conductive traces running along its length. These cables are typically made of plastic or a similar flexible material, and they are often used to connect display screens or other components to a circuit board. Standard FFC connectors are usually designed with a clamping mechanism that holds the cable in place and maintains a reliable connection.

Flexible Printed Circuits, on the other hand, are made from a thin, flexible sheet of material that has conductive traces printed onto its surface. These cables are often used in small electronic devices where space is limited, such as smartphones or digital cameras. FPCs can be designed with different contact patterns and shapes to accommodate a variety of electronic components.

In summary, while both FFC and FPC connectors are flexible, flat cables used for connecting electronic components, FFC connectors are made of a flat, flexible cable, whereas FPC connectors are made from a thin, flexible sheet of material with conductive traces printed on its surface.

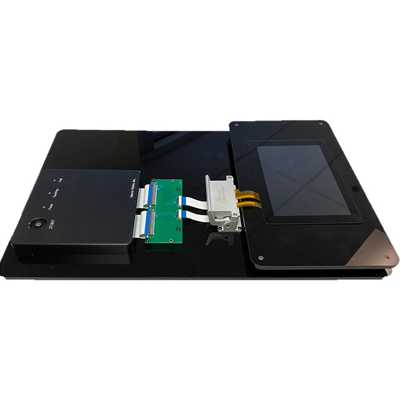

PCAP Touch Screen Test Fixture

The P-CAP tester measures the admittance of nodes where each node is formed by a cross section between a row electrode and a column electrode.

High Speed Cable Tester

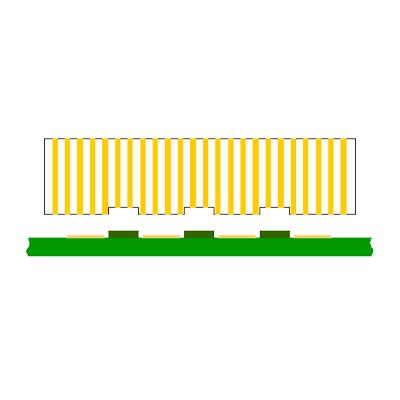

Low profile ZIF and LIF (zero and low insertion force) connectors are used to interface FFC – FPC circuits to PCBs.

Custom Connectors

The Z-Axis Connector Company manufactures custom electronic connectors, commonly known as Elastomeric Connectors.

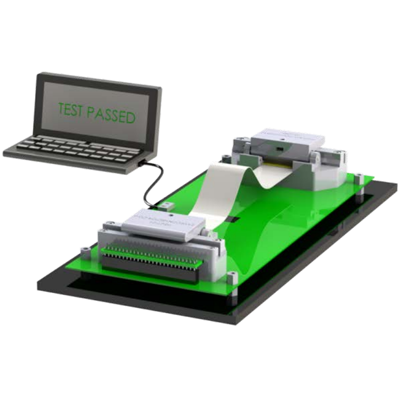

Z-Axis Flex Circuit Test Fixtures

Z-Axis Flex Circuit Test Fixtures are used to connect flex circuits to test equipment. A weak spot in a typical functional test system is where a DUT Flex connects to a circuit board. An obvious method – attaching the flex directly with an FFC or FPC connector – fails. OEM connectors are not designed to withstand extended cycles and break down quickly. When they do, replacement is difficult because they are surface mount components and require a labor-intensive re-work process. Using the Z-Axis Elastomeric Connector Interposer, the connection to the OEM FFC connector becomes permanent and is thereby saved from over-use.

Advantages

- 20,000 plus cycles

- Machined aluminum units are available

- Sturdy actuator

- Fast delivery

- Custom configurations for non-standard flex circuits

- Soft contact to DUT pads

- Easily replaced contact strips

Learn More About Flex Test Fixtures

For more details about custom flex jumper test connectors, please contact us.

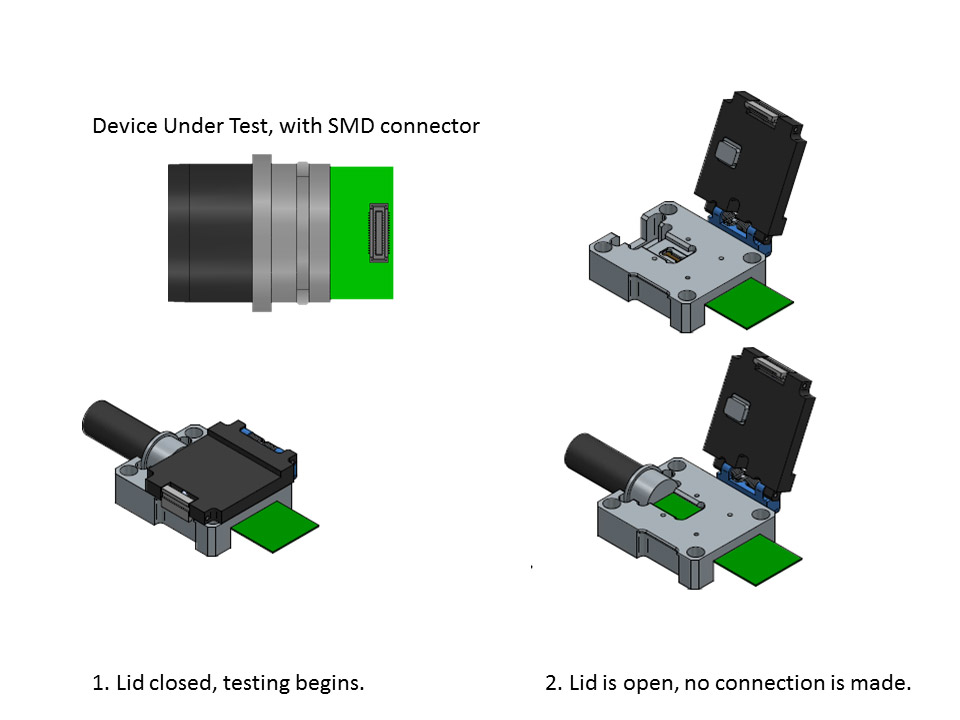

Surface Mount Device Test Fixture

We also offer test fixtures for Surface Mount Devices.

Learn more about our products & capabilities.

Contact Us